Wheat Maize Pneumatic Roller Mill

The machine for grain grinding

The roller mill is an ideal grain milling machine for processing corn, wheat, durum wheat, rye, barley, buckwheat, sorghum and malt. The length of the milling roller is available in 500mm, 600mm, 800mm, 1000mm and 1250 mm.

It can be installed on the second floor for convenient operation or on the first floor to save space. Different surface parameters correspond to different grinding passage, and different intermediate materials.

Features

1. As a flour mill, the MMQ type grain roller mill is perfectly designed for flour milling industry.

2. The milling rolls are running on self-aligning SKF (Sweden) roller bearings housed on a carbon steel beam and located on shock absorbers. Thus the machine vibration can be greatly reduced and the machine operation could become very quiet.

3. The structure of the main base of the roller mill is made of cast iron which is designed for heavy loading capacity. Other frames are welded and appropriately processed by high quality steel plates for eliminating mechanical stress. This special design can further guarantee the limited milling vibrations and noise free operation.

4. The main drive mechanism between motor and fast roller is the 5V high tension belt, while the transmission part between milling rolls is sprocket belt which could absorb the vibration and noise to a great degree.

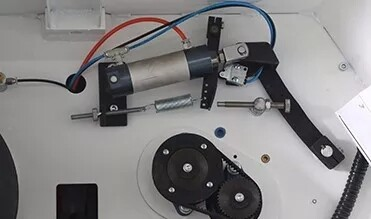

5. The milling rolls of the roller mill are engaged by pneumatic SMC (Japan) air cylinder units installed on both sides of the machine.

6. The milling roller is horizontally installed. The roller set bears all the operational pressure.

7. Horizontal roller configuration and servo-feeder contribute to a perfect grinding performance.

8. Air aspiration design for the roller gap help to reduce the temperature of the grinding roller.

9. Roller is made of centrifugal cast iron, dynamically balanced for a long working span.

Technical Parameters List

| Type/Parameter | Length | Diameter | Weight | Shape Size |

| mm | mm | kg | LxWxH(mm) | |

| MMQ80x25x2 | 800 | 250 | 2850 | 1610x1526x1955 |

| MMQ100x25x2 | 1000 | 250 | 3250 | 1810x1526x1955 |

| MMQ100x30x2 | 1000 | 300 | 3950 | 1810x1676x2005 |

| MMQ125x30x2 | 1250 | 300 | 4650 | 2060x1676x2005 |

Product Details

The material level is controlled by the level sensor plate.

The sensitive flow control and the accurate feeding reaction of the feed roller avoid frequent engagement and disengagement of grinding rollers, which is beneficial to lengthen the grinding roller's service life.

Roller: Double metal centrifugal casting, high strength, and good wear resistance. Unbalance of the dynamic balance ≤ 2g. Total radial run-out < 0.008 mm. The shaft end is treated with 40Cr and the hardness is HB248-286. The hardness of roller surface: Smooth roller is Hs62-68, tooth roller is Hs72-78. Besides, the hardness distribution is uniform, and the hardness difference of the roller is ≤ Hs4.

Feeding Roller: The feeding roller is controlled by a cylinder whose reaction is sensitive.

Blackening treatment is applied to the belt pulley and other castings, which keep it from rust. And easy disassembly.

About Us