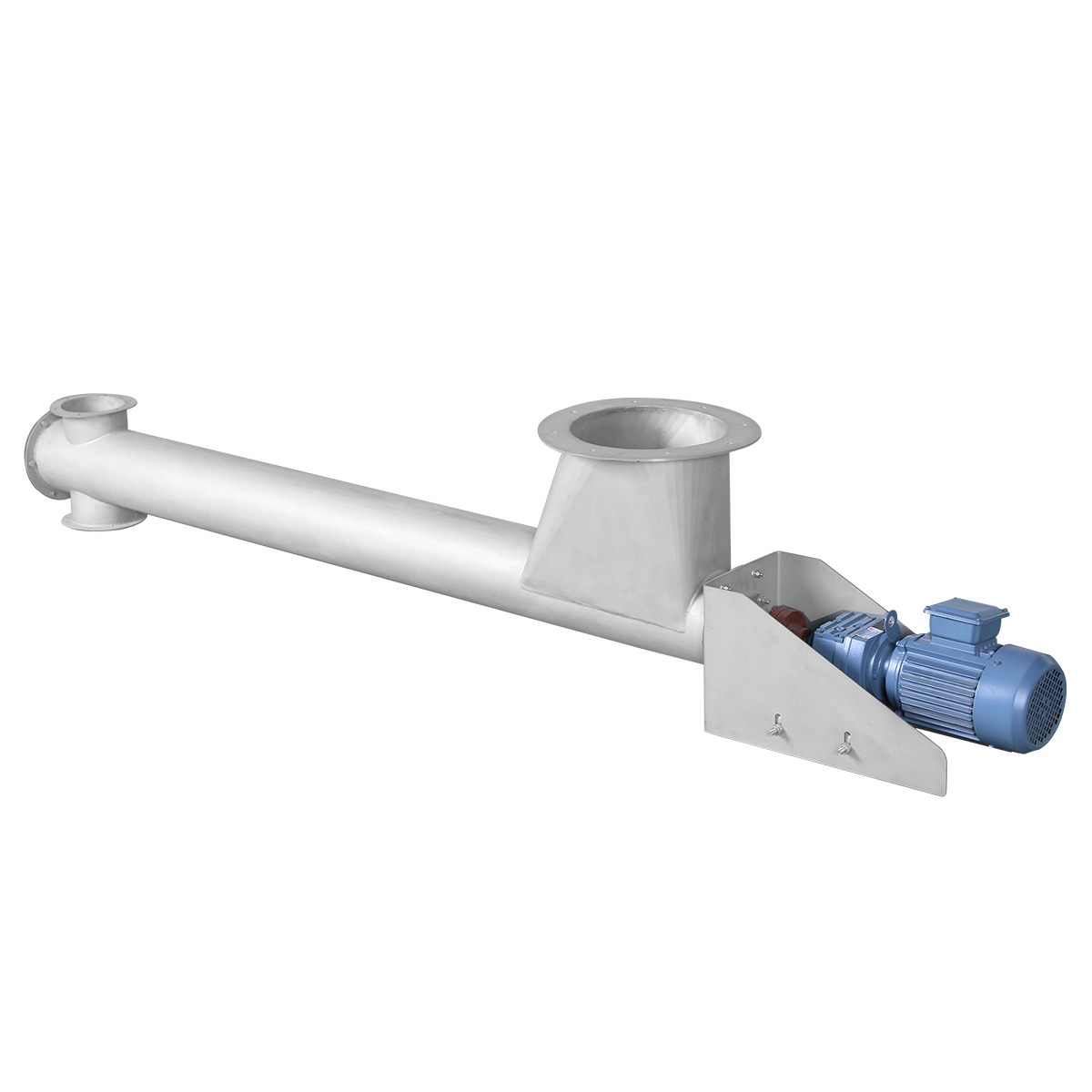

TLSS Wheat Flour Screw Conveyor

Our premium screw conveyor is suitable for conveying powder, granular, lumpish, fine- and coarse-grained materials such as coal, ash, cement, grain, and so on. The suitable material temperature should be less than 180℃. If the material is easy to get spoiled, or agglomerated, or the material is highly adhesive, it is not advisable to convey it on this machine.

A shaft welded with screw is installed in a trough type casing. The granular or pulverulent products are fed into the machine and transferred straight forward to the discharging outlet by the rotating screw welded on the shaft.

To get an ideal conveying facility for a grain screw conveyor, food screw conveyor, fodder conveyor or malt conveyor, you are highly advised to consider our product whose details are listed below.

Feature

1. The equipment comes with modular design and excellent fabricating.

2. The inlets and outlets can be configured as required

3. The dust-tight housing leads to high degree of sanitation.

4. The screw conveyor is easy to maintain.

5. The low operating energy consumption property is available.

6. All the components are made of food-grade materials or come with special food-grade coating.

7. An overflow gate with personal protection switch is available.

8. The inlet trough is equipped with a progressive solid-flight screw for uniform storage bin discharge.

9. The intermediate outlet of the screw conveyor comes with a slide gate.

10. The multi-layer anti-corrosive coating is used for outdoor applications.

11. A direct drive mechanism is available.

12. In the screw conveyor, there is a flexible coupling between the drive and the screw shaft.

13. The horizontal mode and inclined mode are both available for the material conveying, distribution, collection, mixing and discharge.

14. The screw shaft connects with the hanging bearing, headshaft, tailshaft by embedded connections. Thus axial movements are not needed for the installation, and detaching, making the repairing quite convenient.

15. The pedestals for the headshaft and tailshaft are both outside of the casing of the screw conveyor. Each bearing comes with multi-layer sealing technology to extend the bearing's service life.

Optional feature

1. The stainless steel screw and trough could be added for wheat dampening or flour to get better sanitation.

2. The paddle-type screw is adopted for mixing.

3. Customized coat of paint is optional for our screw conveyor.

4. The bottom gates are optional for easy cleaning of the screw and trough.

Product Details

The material inlet is large enough to reduce the material blocking in the bin and make the material discharge smoothly.

Complete Screw blade: one side of the screw blade clings to the shaft, forming a complete screw surface, and have a good conveying effect.

Different screw interval arrangement structure of material inlet blade: Better regulation of material flow volume.

About Us