500 Ton Wheat Flour Mill Plant

These machines are mainly installed in reinforced concrete buildings or steel structural plants, which are generally 5 to 6 stories high (including the wheat silo, flour storage house, and flour blending house).

Our flour milling solutions are mainly designed according to American wheat and Australian white hard wheat. When milling a single kind of wheat, the flour extraction rate is 76-79%, while the ash content is 0.54-0.62%. If two kinds of flour are produced, the flour extraction rate and ash content will be 45-50% and 0.42-0.54% for the F1 and 25-28% and 0.62-0.65% for the F2.

| Model | CTWM-500 |

| Capacity | 500TPD |

| Roller Mill Model | Pneumatic/Electric |

| Installation Power(kw) | 950-1000(Without Blending) |

| Worker Per Shift | 10-12 |

| Water Consumption(t/24h) | 25 |

| Space(LxWxH) | 76x14x30m |

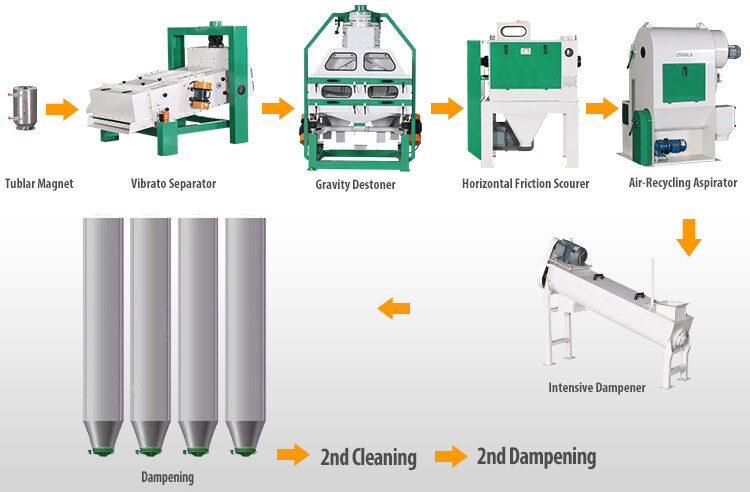

Cleaning Section

In the cleaning section, we adopt drying-type cleaning technology. It normally includes 2 times sifting, 2 times scouring, 2 times de-stoning, one time purifying, 4 times aspiration, 1 to 2 times dampening, 3 times magnetic separation, and so on. In the cleaning section, there are several aspiration systems that can reduce the dust spray-out from the machine and keep a good working environment. This is a complicated thorough flow sheet that can remove most of the coarse offal, middle size offal, and fine offal in the wheat.

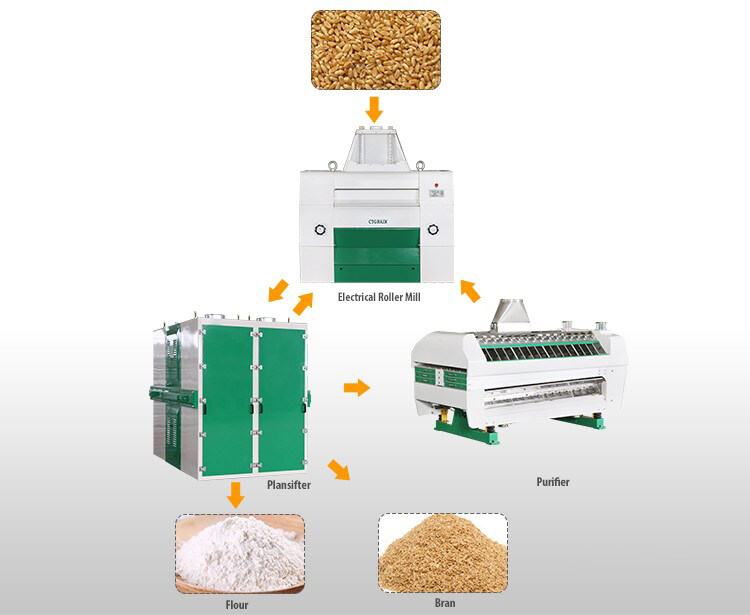

Milling Section

In the milling section, there are four types of systems to mill the wheat to flour. They are the 4-Break system, 7-Reduction system,1-Semolina system, and 1-Tail system. The whole design will insure less bran is mixed into the bran and the flour yield is maximized. Because of the well-designed pneumatic lifting system, the whole mill material is transferred by a High-pressure fan. The milling room will be clean and sanitary for aspiration adoption.

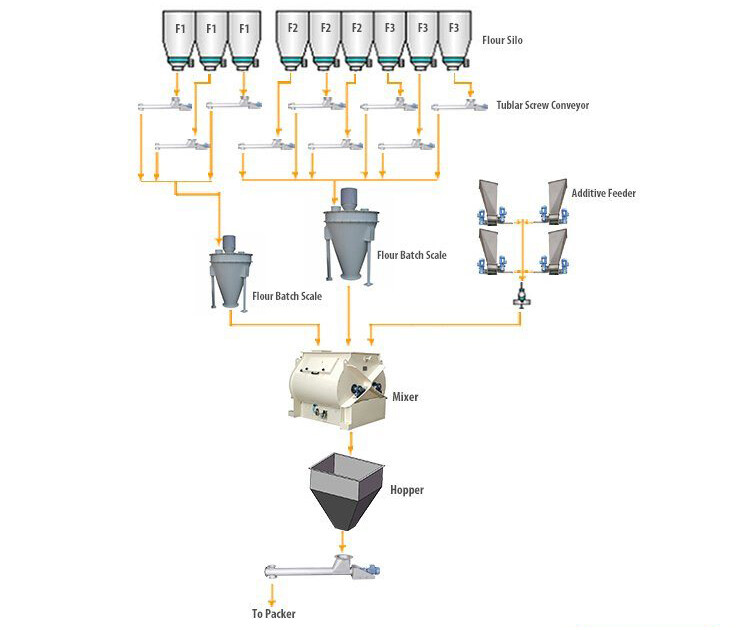

Flour Blending Section

The flour blending system mainly consists of a pneumatic conveying system, bulk flour storage system, blending system, and final flour discharging system. It is the most perfect and efficient way to produce tailored flour and keep the stability of flour quality. For this 200TPD flour mill packing and blending system, there are 3 flour storage bins. The flour in storage bins is blown into 3 flour packing bins and packed finally.

Packing Section

The packing machine has features of high measuring accuracy, fastpacking speed, reliable and stable working. It can weigh and count automatically, and it can accumulate weight. The packing machine has the function of fault self-diagnosis. The packing machine is with sealed type bag-clamping mechanism, which can prevent material from leaking out.The packing specification includes 1-5kg,2.5-10kg,20-25kg,30-50kg.The clients can choose different packing specifications according to requirements.

Electrical Control And Management

We will supply an electrical control cabinet, signal cable, cable trays and cable ladders, and other electrical installation parts. The substation and motor power cable are not included except customer especially required. PLC control system is an optional choice for customers. In a PLC control system, all the machinery is controlled by Programmed Logical Controller which can ensure the machinery runs stably and fluently. The system will make some judgments and do reactions accordingly when any machine is at fault or stopped abnormally. At the same time, it will alarm and remind the operator to settle the faults.

About Us