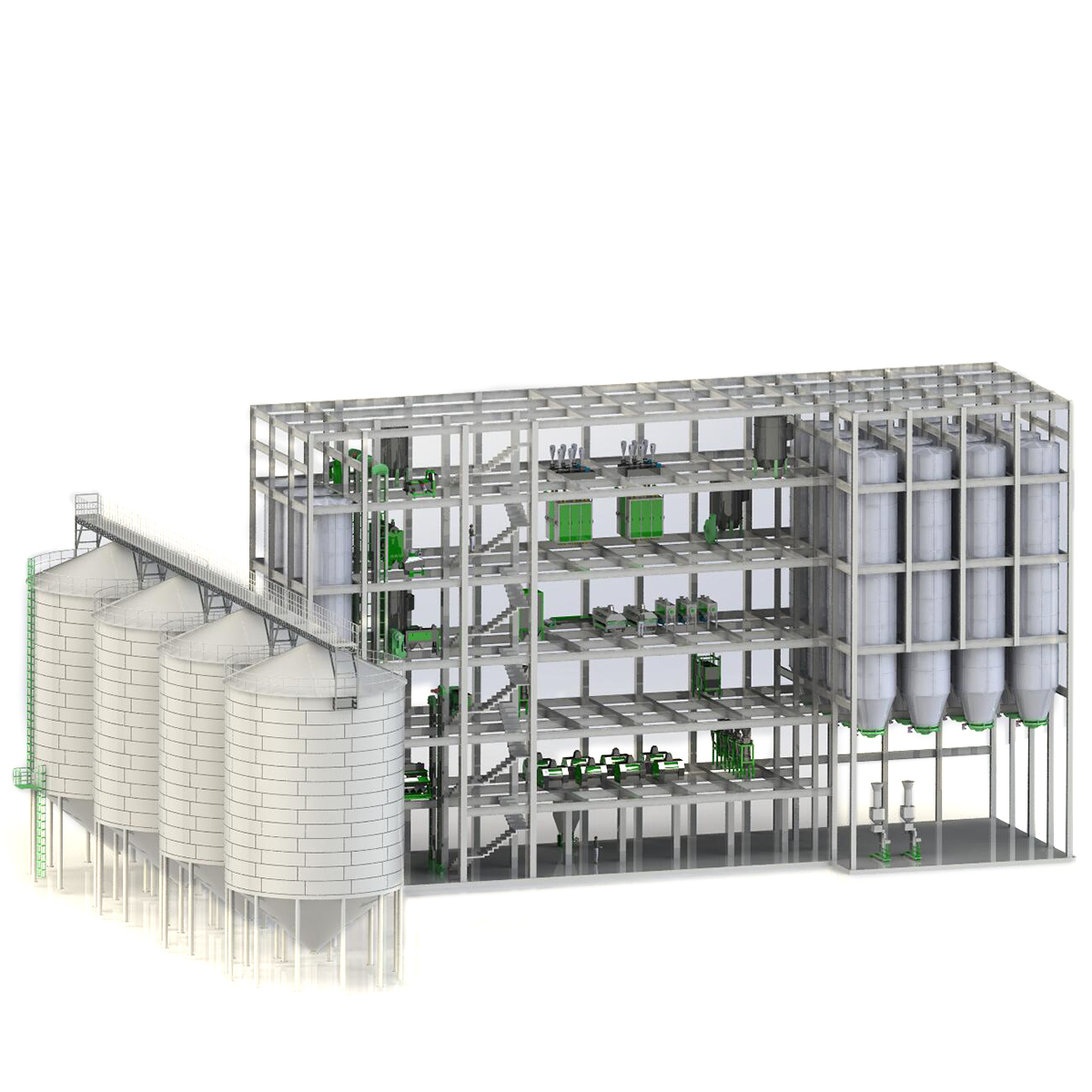

Flour mills are essential for processing wheat into flour. To produce high-quality flour, it is very important to have reliable and efficient flour mill equipment. The main equipment of the flour mill includes:

1. Cleaning equipment – This equipment removes impurities such as stones, sticks, and husks from the wheat before it is ground into flour. Including vibrating screens, magnetic separators, aspirators, and other machinery.

2. Milling equipment – This is the heart of the flour mill where the wheat is ground into flour. There are many types of milling equipment such as roller mills, hammer mills, and stone mills. These machines use different techniques to break down the wheat grains into flour.

3. Screening Equipment – After the wheat is ground, the flour needs to be separated from any remaining impurities. Sieving equipment such as square sieves and purifiers are used to separate flour according to its particle size and density.

4. Packing equipment – After the flour is sifted, it can be packed into bags or containers. Packaging equipment such as fillers, baggers, and sealers can automate this process and ensure the flour is packaged securely.

5. Control System – Modern flour mills use computer-based control systems to monitor and regulate the entire milling process. This includes monitoring temperature and humidity levels, adjusting the milling process, and managing the packaging and shipping of flour.

In conclusion, the quality of flour produced by a flour mill depends largely on the type and efficiency of the equipment used. We are constantly innovating and developing new technologies to improve the efficiency and safety of the milling process.

Post time: Apr-21-2023